※レポートは、MarketsandMarkets社が作成したもので英文表記です。

レポートの閲覧に際してはMarketsandMarkets社のDisclaimerをご確認ください。

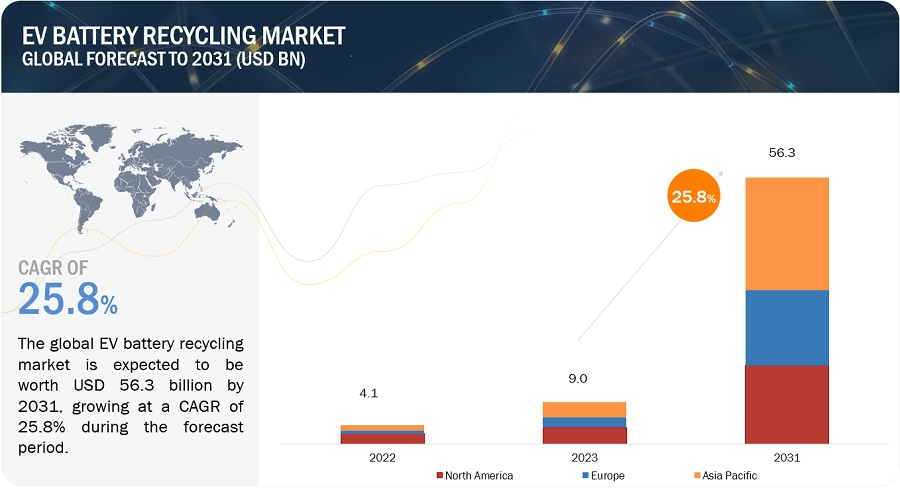

The global EV Battery Recycling Market is projected to grow from USD 9.0 billion in 2023 to USD 56.3 billion by 2031, at a CAGR of 25.8 % during the forecast period. Use of EV vehicles in Automotive sectors and advancement in lithium-ion battery are driving the growth in EV Battery Recycling market. The recycling of EV batteries is crucial to reduce waste, save valuable resources, and protect the environment. Automotive manufacturers are collaborating with recycling companies to recycle EV Batteries

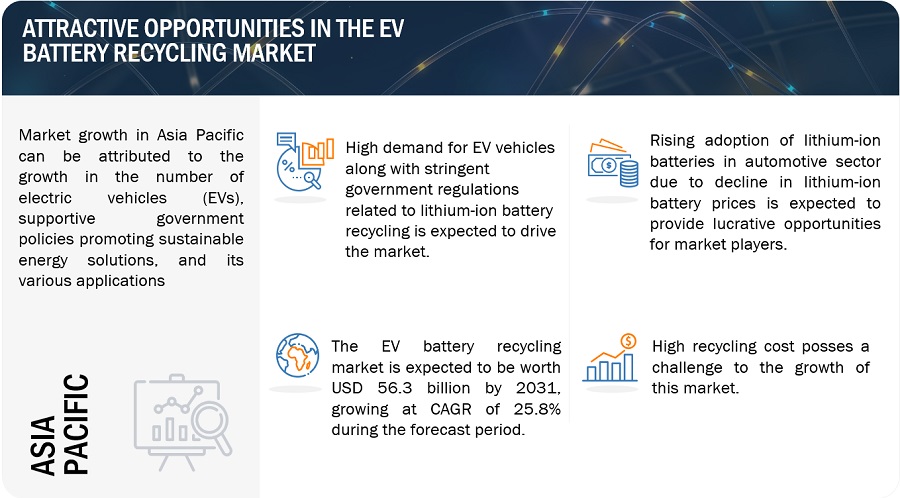

Attractive Opportunities in the EV Battery Recycling Market

Market Dynamics:

Driver: Increase in demand for recycled products and materials

The increasing interest in utilizing recycled materials and batteries is anticipated to promote research and development in the recycling of both batteries and materials. The upward path in material costs, coupled with a growing demand for eco-friendly or recycled products, is projected to create various sectors for growth within the battery recycling market. The mounting interest in recycled products and materials serves as a significant change, expected to have a substantial impact on the electric vehicle battery recycling market. This heightened demand is driven by a worldwide movement toward sustainable practices, a heightened environmental consciousness, and a growing awareness of the limited availability of natural resources.

Restraints: Safety issues related to storage and transportation of spent batteries

Spent batteries has hazardous chemicals, including acids and heavy metals such as mercury. In July 2007, a fire sparked by a lithium-based battery led to the ignition of over 132,000 liters of chemicals, resulting in the closure of two major highways in the UK. These batteries retain some charge after use, posing a risk of unexpected discharges that can harm people or property. It's crucial to handle all batteries cautiously, assuming they still have a charge unless properly labeled, and store them carefully, especially small batteries that could be swallowed by children. Larger lithium-based batteries, commonly found in cars, may be incorrectly identified as lead-acid batteries if not labeled accurately by local manufacturers. To prevent hazards, these batteries must be separated from used lead-acid batteries before storage. Concerns about the potential dangers associated with used batteries have led to regulations by state or national governments governing their storage and transportation.

Opportunity: Rising adoption of lithium-ion batteries due to decline in prices

Expensive lithium-ion batteries have held back market growth since the 1990s. These batteries have various parts, and some are subsidized. The main part, called the cell, makes up about half the cost, with the rest going to electronics, assembly, and packaging. Recent promises from battery and car companies suggest a significant price drop. A Bloomberg NEF survey shows the average battery pack cost went down to USD 137 per kWh in 2020, dropping 88% since 2010. Predictions say prices might go as low as USD 58 per kWh by 2030 and USD 44 per kWh by 2035. Tesla's Gigafactory-1 is one effort to increase battery production and lower prices. With advancements like large-scale manufacturing and better technology, lithium-ion battery prices are expected to decrease. This decline is likely to boost the renewable energy and grid storage markets, favoring lithium-ion batteries and increasing their market share. As a result, there could be a growing demand for recycling used automotive lithium-based batteries.

Challenge: High recycling cost and dearth of technologies

The Centre for Energy Economics (CEE) reports that globally, only 1-3% of lithium is recovered from all applications. Companies like Toxco (US) and Umicore (Belgium) are working on technologies to extract lithium from batteries. However, challenges for the industry include the high recycling costs, lack of proper storage for used batteries, and a shortage of recycling technologies. Recycling lithium-ion batteries is costly, and traditional methods can be energy-intensive. This makes recycling economically challenging compared to extracting materials from raw sources. Additionally, the diverse chemistries of lithium-ion batteries, varying among manufacturers, make it difficult to develop universal and cost-effective recycling processes. The need for customized recycling solutions adds complication and cost to the process, negatively impacting the market for electric vehicle battery recycling.

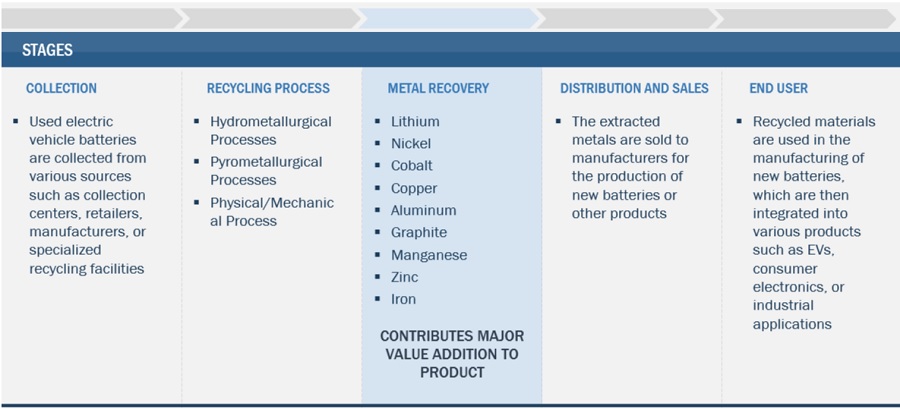

Ev Battery Recycling Market : Ecosystem

Prominent companies in this market include well-established, and financially stable manufacturers of EV battery recycling market. These companies have been operating in the market for several years and possess a diversified product portfolio and strong global sales and marketing networks. Prominent companies in this market include).

"Lithium Iron Phosphate, by battery chemistry, is estimated to account for the highest CAGR during the forecast period."

The rising popularity of lithium iron phosphate (LFP) electric vehicle (EV) batteries can be attributed to several compelling factors. LFP batteries excel in safety, boasting a reduced risk of overheating and fire as compared to other lithium-ion batteries. LFP batteries are environmentally sustainable, being non-toxic and recyclable, making them an eco-friendly choice. With a wide operating temperature range, they prove versatile for various applications, including those facing extreme temperatures. Cost-effectiveness is another advantage, as iron and phosphorus, the key components, are readily available and affordable globally.

"E-Bikes, by source , is estimated to account for the highest CAGR during the forecast period."

E-Bikes by source contributes to have highest CAGR during the forecast period as electric vehicle (EV) batteries in e-bikes is driven by several key advantages. EV batteries, particularly lithium-ion and lithium-iron-phosphate (LFP) types, offer higher energy density, ensuring longer range and improved e-bike performance. Safety is enhanced, with lithium-ion batteries being less susceptible to thermal runaway and oxygen release in case of fire compared to lead-acid batteries

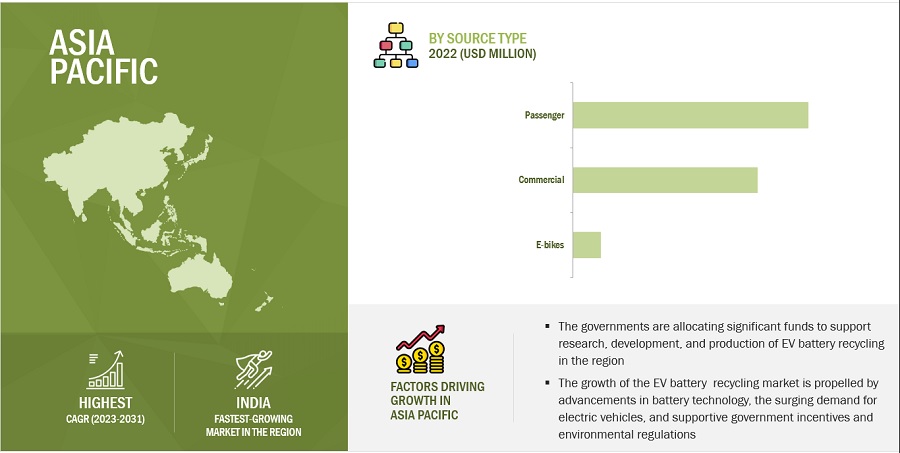

"Asia Pacific is estimated to account for the highest CAGR during the forecast period."

The demand for EV batteries in Asia Pacific is significant, driven by the increasing adoption of EVs in emerging economies. Growing investments by leading automotive OEMs to set up battery manufacturing and recycling facilities in the region, and rising government initiatives to support EV battery manufacturing, and EV battery recycling are some of the factors driving the growth of the EV battery recycling market in the Asia-Pacific region.

Source: Secondary Research, Expert Interviews, and MarketsandMarkets Analysis

Key Market Players

Major companies in the EV Battery Recycling Market include Contemporary Amperex Technology Co., Limited. (China), Glencore (Switzerland), GEM Co., Ltd. (China), ERAMET (France), Li-Cycle Corp (Canada), Umicore (Belgium) among others. A total of 23 major players have been covered. These players have adopted product launches, agreements, joint ventures, investments, acquisitions, mergers, and expansions as the major strategies to consolidate their position in the market.

Get online access to the report on the World's First Market Intelligence Cloud

- Easy to Download Historical Data & Forecast Numbers

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

Get online access to the report on the World's First Market Intelligence Cloud

- Easy to Download Historical Data & Forecast Numbers

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

Scope of the Report

|

Report Metric |

Details |

|

Market Size Available for Years |

2017–2031 |

|

Base Year Considered |

2022 |

|

Forecast Period |

2023–2031 |

|

Forecast Units |

Value (USD Billion/Million) and Volume (Units) |

|

Segments Covered |

Battery Chemistry , Sources,Process and Region. |

|

Geographies Covered |

Asia Pacific, Europe, and North America |

|

Companies Covered |

The major market players include Contemporary Amperex Technology Co., Limited. (China), Glencore (Switzerland), GEM Co., Ltd. (China), ERAMET (France), Li-Cycle Corp (Canada), Umicore (Belgium) ,Accurec-Recycling GMBH (Germany), Fortum (Finland) ,Cirba solutions (US) ,Neometals Ltd.(Australia),Redwood Materials Inc. (US),Ecobat (US),Stena Recycling (Sweden) ,TES (Singapore),Ace Green Recycling, Inc. (USA), ,Shenzhen Highpower Technology Co., Ltd (China) and others. |

This research report categorizes the EV battery recycling market market based on Battery Chemistry , Sources,Process and Region.

Based on battery chemistry Type, the EV battery recycling market market has been segmented as follows:

- Lithium nickel manganese cobalt

- Lithium iron phosphate

- Lithium titanate oxide

- Lithium manganese oxide

- Lithium nickel cobalt aluminum oxide

Based on Process, the EV battery recycling market market has been segmented as follows:

- Hydrometallurgical process

- Pyrometallurgy process

- Physical/mechanical process

Based on Sources, the EV battery recycling market market has been segmented as follows:

- Commercial

- Passenger

- E-bikes

Based on region, the EV battery recycling market market has been segmented as follows:

- Asia Pacific

- Europe

- North America

Recent Developments

- In Sep-2022 Umicore and PowerCo had announced the founding of a joint venture for precursor and cathode material production in Europe. From 2025 onwards, the joint venture will supply PowerCo's European battery cell factories with key materials. It also aims to include elements of refining and battery recycling based on Umicore's technology.

- In March 2022, Neometals and Mercedes-Benz confirmed their plans for a battery recycling joint venture. Through the JV, the companies intend to build a 2,500-ton-per-year lithium-ion battery recycling plant in Germany.

- In November 2022, Li-Cycle Corp. has announced a strategic partnership with Vines Energy Solutions, a battery & cell pack manufacturer and a member company of Vingroup. Through this partnership, Li-Cycle provided its recycling solutions to Vines Energy Solutions

Frequently Asked Questions (FAQ):

What is the key driver for the ev battery recycling market?

Growing adoption of EVs and plug-in vehicles as a driving force for the EV battery recycling market

Which region is expected to register the highest CAGR in the EV Battery Recycling Market during the forecast period?

The EV Battery Recycling Market in Asia Pacific is estimated to register the highest CAGR during the forecast period.

What is the major source of EV battery ?

The passenger segment holds a prominent position in the EV battery recycling market due to the widespread use of passenger cars and the increasing adoption of electric vehicles (EVs). As the demand for electric passenger cars continues to rise, the number of spent EV batteries from this segment also increases, driving the need for effective recycling solutions.

Who are the major players of the EV battery recycling market?

The key players operating in the market include Glencore (Switzerland), GEM Co., Ltd. (China), ERAMET (France), Li-Cycle Corp (Canada), Umicore (Belgium).

What is the total CAGR expected to record for the EV Battery Recycling Marketduring 2023-2031?

The market is expected to record a CAGR of 25.8 % from 2023-2031. .